Printed Injection Molded Plastic Parts White PP For Power Bank

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | ABS, TPE, TPU, PP, PC, PET.... | Color | White, Black, Or Pantone |

|---|---|---|---|

| Size | Less Than 400x400x200mm | Surface | Matt, Glossy, Plated... |

| Tolerance | 0.01-0.05 | ||

| Highlight | Printed Molded Plastic Parts,PP Molded Plastic Parts,Power Bank Injection Plastic Part |

||

Printed Molded Injection Plastic Part White PP For Power Bank Etc

What is injection molding?

Injection molding is a manufacturing technology for the mass production of identical plastic parts with good tolerances. In Injection Molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. The materials used in Injection Molding are thermoplastic polymers that can be colored or filled with other additives.

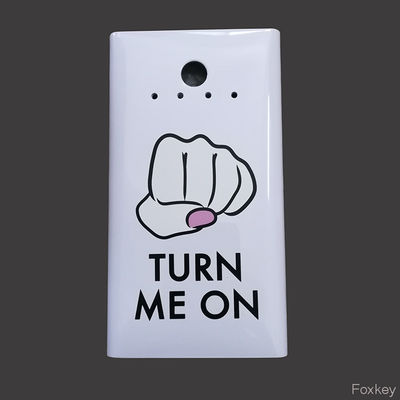

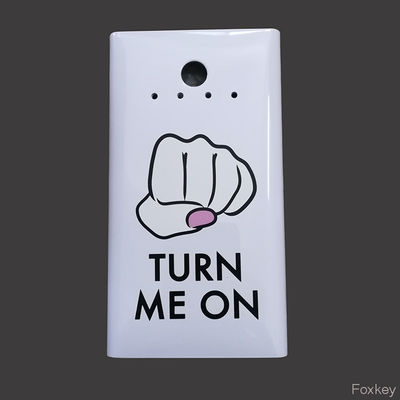

Printed Plastic part for Power bank

![]()

![]()

Molded plastic part for funny cup

![]()

Silver Plated plastic ring with thread

![]()

Molded Plastic part group for water purify systems, many material

![]()

![]()

Plastic injection part for shower head with silver plated

![]()

Plastic injection plastic part for LED digital panel

![]()